| Sign In | Join Free | My qualitytoyschina.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My qualitytoyschina.com |

|

Brand Name : MG

Model Number : MGDM-3.7

Certification : CE, ISO9001:2008

Place of Origin : China

MOQ : 1 set

Payment Terms : T/T, L/C, D/A, D/P, MoneyGram, Western Union

Supply Ability : 20 sets per month

Delivery Time : 20-25 working days

Packaging Details : Stand seaworthy packaging

Price : negotiable

Product name : Dry mix plant

Condition : New

Capacity : 30-50T/H

Color : Grey/White/Blue or customized

Warranty : 12 months

Advantage : Professional manufacturer

After-sales services : Engineer available to service machinery overseas

Formulation : Provide for free

Packaging : As requirement

Total Height : 15-25m

High Performance Full Automatic Dry Mix Mortar manufacturing Plant

Descriptions of MG automatic dry mix plant:

Dry mix mortar mixing plant is mainly composed of raw materials storage system, lifting & conveying system, weighing system, mixing system, packing system dust collection system and control system.

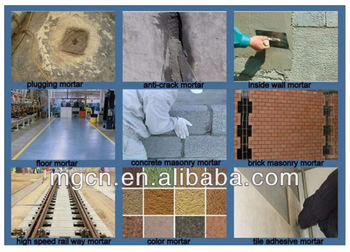

It's always used for mixing and producing all kinds of dry powder,such as mansory mortar, foor mortar, tile mortar, brick mortar, filing mortar, insulation mortar and so on.

Working site of MG full automatic dry mix mortar manufacturing plant:

Materail storag silo equip on the dry mix mortar plant:

Mixer equip on the full automatic dry mix mortar plant:

Steel platform equip on the full automtic dry mix mortar plant:

PLC Control cabinet equip on the full automatic dry mix mortar plant:

Technical parameters of MG automatic dry mix mortar plant:

| Automatic Dry Mix Plant | |||

| Capacity | 30-80t/h(depending on applied formula) | ||

| Production circle | 3-5minutes | ||

| Assumed bulk material density | 1.4kg/m3 | ||

| Number of circles/hour | 15-20(depending on applied formula) | ||

| Sand dosage tolerance | ±1% | ||

| powder dosage tolerance | ±1% | ||

Application of MG automatic dry mix plant:

Dry mortar plants suitable for practically all demands, such as:proprietary adhesive and mortars for aerated concrete; glue mortar for ceramic wall tiles; masonry mortar; skim coat; inside plaster; outside stucco; concrete; floor screed Benefits for the builder; Usage for many kinds of construction material, such as autoclaved aerated concrete (AAC), rock, calcium silicate bricks, masonry blocks, tiles, joints, etc; Application manually or with rendering/ plastering machines; Available in paper bags or in bulk

Successful projects of MG dry mix mortar plant project:

We are professional manufacturer of dry mortar machines, our company dedicated in this field for more than 20 years, we alreays provide our customer turnkey project of dry mortar plant from working site planning to machine installation and commissioning, formula, opeation training, technical support etc. Escort for your sucess!

|

|

High Performance Full Automatic Dry Mix Mortar Manufacturing Plant Images |